Experts in the rubber industry

LEHVOSS Italia distributes in Italy a huge variety of products including synthetic rubbers, mineral fillers, and with the well know LUVOMAXX® brand, chemicals and carbon black.

Thanks to our expertise and knowledge of the rubber field, we are in relationship with many raw materials sources and we are able to offer to our valuable customer the best technical solution at the best price.

Chemicals, Additives

Phenolic resins

P-tert-octylphenol formaldehyde tackifying resins (RT 11** Series)

P-tert-octylphenol formaldehyde tackifying resins are a kind of alkylphenol formaldehyde tackifying resins. There will be no chemical reactions under vulcanization temperature for this kind of resin because the alkyl group in its molecular structure is in the opposite position of phenol hydroxyl group, thus it has non-thermal reactivity. The compatibility between the resin and various kinds of synthetic rubber is excellent.

Advantages:

- Scorch time can be prolonged

- Improved processing properties

- Easy soluable and dust-free product

Typical shelf life is 12 months.

| Grade | Appearance | Ring and Ball Softeining Point [°C] | Ash content 600°C [%] | Acid value [mgKOH/g] | Application |

|---|---|---|---|---|---|

| RT 1101 | Light yellow pellets | 92 - 102 | ≤ 0.5 | 30 - 54 | General purpose octylphenol formaldehyde tackifier resin |

| RT 1102 | Light yellow to yellow pellets | 85 - 95 | ≤ 0.5 | 30 - 54 | General purpose low melting point tackifier resin |

| RT 1107 | Light yellow to yellow pellets | 92 - 102 | ≤ 0.5 | 25 - 45 | Tackifier resin, also for EPDM adhesives |

P-tert-butylphenol formaldehyde tackifying resins (RT 12**, RT 15** Series)

P-tert-butylphenol formaldehyde tackifying resin is a kind of alkylphenol formaldehyde tackifying resin. Being a thermoplastic phenolic resin, it will not show chemical reactions under the vulcanization temperatures. Benefited from its good compatibility with all kinds of rubber, it provides excellent tackifying performance, especially for styrene butadiene, nitrile butadiene and chloroprene. This kind of resin is suitable for the tire rubber products which have high requirements of tackiness.

Typical shelf life is 12 months.

| Grade | Appearance | Ring and Ball Softeining Point [°C] | Ash content 600°C [%] | Volatile content 105°C, 2h [%] | Application |

|---|---|---|---|---|---|

| RT 1205 | Light brown to dark brown pellets | 135 - 145 | ≤ 0.5 | ≤ 0.5 | Super tackifier resin |

| RT 1560 | Light yellow to yellow pellets | 126 - 140 | ≤ 0.5 | ≤ 0.5 | Alkylphenol super tackifier resin |

Reinforcing phenolic resins (RT 2***)

Reinforcing phenolic resins include straight phenolic resins and modified phenolic resins which show improved compatibility with rubber. The reinforcing resin can play the role of tackifying, plasticizing and softening of the rubber compounds before vulcanization to improve the processing performance. The performance of hardness, toughness, tear resistence, abrasion resistence will be improved.

This is achieved by the interpenetration of the three-dimensional mesh structure of hexamethylene tetramine and other methylene donors during their vulcanization with the three-dimensional mesh structure of the rubber.

RT60** is a kind of biomass modified reinforcing agent, which can be used to replace part of carbon black to improve the strength of tires and other rubber products. It can effectively reduce the heat built up and improve the thermal performance of the rubber material.

RT62** is a class of 100% bio-based reinforcing agent. It can partly replace the process oil during mixing to reduce the Mooney viscosity of the rubber material to reduce heat generation. Network interpenetration with rubber vulcanization network and reaction with the accelerator will occur to improve the modulus of the rubber materials during vulcanization.

Typical shelf life is 12 months.

| Grade | Appearance | Ring and Ball Softeining Point [°C] | Free phenol [%] | Ash content 800°C [%] | Application |

|---|---|---|---|---|---|

| RT 2101 | Yellowish-brown to brownish red pellets | 92 - 103 | ≤ 1.0 | ≤ 0.5 | Tall oil-modified resin |

| RT 2201 | Yellowish-brown to brownish red pellets | 90 - 102 | ≤ 1.0 | ≤ 0.5 | CNSL modified resin |

| RT 2303 | Light yellow to yellow pellets | 106 - 116 | ≤ 0.5 | ≤ 0.5 | High purity phenolic resin |

| Grade | Appearance | Viscosity [mPas] | Volatile content 105°C, 2h [%] | Application |

|---|---|---|---|---|

| Development products | ||||

| RT 6001 | Light yellow to dark yellow powder | - | ≤ 3.0 | Bio-based content 10 - 30% |

| RT 6201 | Dark brown liquid | 10,000 - 30,000 | - | 100 % bio-based |

Bonding resins (RT 31** Series)

The low content of free resorcinol in resorcinol formaldehyde resins can effectively solve the problems of high temperature sublimation of resorcinol in the mixing process. This affects the operating environment and the health of operators as well as the phenomenon of resorcinol on the surface of the compound, such as “spraying frost”. In combination with methylene donors bonding resins provide excellent adhesive properties leading to significantly improved bonding strength between rubber and fabrics made of various fibers and steel wire. Consequently the durability of the finished tire will be improved.

Typical shelf life is 12 months.

| Grade | Appearance | Ring and Ball Softeining Point [°C] | Free phenol / resorcinol [%] | Volatile content 105°C, 2h [%] | Application |

|---|---|---|---|---|---|

| RT 3101 | Brown red to black pellets | 98 - 110 | ≤ 4.0 free resorcinol | ≤ 0.5 | Modified Resorcinol Formaldehyde Resin for general purpose application |

| RT 3104 | Light yellow to red pellets | 98 - 108 | ≤ 0.5 free phenol | ≤ 0.5 | Modified Phenolic Resin with low content of free phenol |

| RT 3106 | Light yellow to yellow pellets | 108 - 120 | ≤ 1.0 free phenol | ≤ 0.5 | Modified Phenolic Resin with higher softening point to improve adhesion between rubber and steel/fiber fabrics |

Vulcanizing resins (RT 4*** Series)

Vulcanizing resins are a kind of thermo-reactive alkylphenol resins. They show good adhesive strength at both room temperature as well as at high temperatures in the adhesive system with chloroprene rubber as the main component. They are mainly used in chloroprene rubber adhesives and is suitable for press-fit adhesive formulation systems with excellent properties such as tack-holding, durability, high-temperature stability, high tensile strength and low elongation.

Product applications:

Mainly used in chloroprene rubber adhesive, they can also be used as vulcanizing agent for natural rubber, styrene butadiene rubber, nitrile rubber and butyl rubber, suitable for tires, vulcanized capsules, conveyor belts, heat-resistant steam rubber products, etc. They are also applied in coating, textile, packaging, printing ink and other industries.

Typical shelf life is 12 months.

| Grade | Appearance | Ring and Ball Softeining Point [°C] | Hydroxymethyl content [%] | Application |

|---|---|---|---|---|

| RT 4101 | Light yellow to yellow block | 100 - 125 | 11 - 16 | Vulcanizing resin based on butylphenol |

| RT 4202 | Light yellow to yellow block | 85 - 95 | 8 - 12 | Vulcanizing resin based on octylphenol |

| RT 4204 | Light yellow to yellow lumps | 75 - 95 | 7 - 12 | Vulcanizing resin based on brominated octylphenol |

Functional resins for tread rubber (RT 5*** Series)

Functional resins for tire tread rubber are a kind of modified aromatic resins. They have good compatibility with rubber and excellent process ing performance. The use of RT51** series resins can effectively improve the tire tread tear resistance, cut resistance and resistance to chipping and chunking. RT52** series resins can significantly improve the tire’s anti-slip and other properties without affecting the rolling resistance. And at the same time, they show excellent thermal stability and have less impact on physical properties of the vulcanized rubber.

Product applications:

RT5*** products are mainly used in the industries of tires, technical rubber products, adhesive tapes.

Typical shelf life is 12 months.

| Grade | Appearance | Ring and Ball Softeining Point [°C] | Volatile content 105°C, 2h [%] | Application |

|---|---|---|---|---|

| RT 5101 | Yellow to brown red pellets | 95 - 110 | ≤ 0.5 | Tear resistant resin |

| RT 5201 | White pellets | 98 - 108 | ≤ 0.5 | Wet-skid resistant resin |

Impregnating resin for fabric (RT 7***Series)

Compatibility, bonding strength and heat-resistant strength of rubber compounds can be improved by the use of RT 7500. This kind of resorcinol resin has a good compatibility thus simplifying the dip process. Its curing temperature is low and curing time is short. It is a good adhesive for tire cord fabric with its high adhesive strength. It shows excellent stability since it will not polymerize during storage.

Product applications:

It is mainly used to treat organic fibers such as polyester, nylon or aramid.

Typical shelf life is 12 months

| Grade | Appearance | Viscosity [mPas] | PH | Solid content 135°C, 1h [%] | Application |

|---|---|---|---|---|---|

| RT 7500 | Dark red liquid | 3,500 - 4,500 | 1 - 3 | 73 - 77 | Tire cord fabric |

Any application-related advice given by us merely constitutes a non-binding indication – also with regard to any property rights of third parties – which does not release the customer from their duty to conduct their own examination of the products delivered by us. Processing, application and use of our products are the sole responsibility of the customer. We guarantee impeccable quality of our goods in accordance with our general terms and conditions of sale and delivery.

If you are looking for a pure substance, a formulation or a special mix of products fully developed to your applications, when you will get in touch with us you could get all of this from only one source with the packaging you will need.

- RUBBER ACCELERATORS (PURE/SUPPORTED ON RUBBER)

- SULFUR (SUPPORTED /OLEATED PWD)

- SULFUR DONOR (PURE/SUPPORTED ON RUBBER)

- ANTIOXIDANTS (PURE/SUPPORTED ON RUBBER/DRY LIQUIDS)

- ANTIOZONANTS

- ANTIDEGRADANTS

- CO-AGENTS FOR RADICAL CROSSLINKING

- ORGANOSILANE (PURE/DRY LIQUIDS)

- HYDROCARBON RESINS

- METAL OXIDES

- PEPTISERS

- SPECIAL PLASICZERS (DRY LIQUIDS)

- BLOWING AGENTS (PURE/SUPPORTED/OLEATED PASTE)

- RETARDERS

- FLAME RETARDANTS

Learn more about the raw materials for the rubber industry from Lehmann&Voss&Co.: www.lehvoss.de/en/Rubber

Synthetic rubber

Our partners are global leaders in the production of synthetics rubbers as:

NBR, SBR, BR, EPM, EPDM, CR, SBS

| Product | ACN (%) | Viscosity (ML 1+4 at 100°C) |

|---|---|---|

| KNB 1845 | 18 | 45 |

| KNB 25 LM | 28 | 50 |

| KNB 25 M | 28 | 60 |

| KNB 25 H | 28 | 80 |

| KNB 3345 | 33 | 45 |

| KNB 35 LL | 34 | 33 |

| KNB 35 L | 34 | 41 |

| KNB 35 LM | 34 | 50 |

| KNB 35 M | 34 | 60 |

| KNB 40 M | 41 | 60 |

| KNB 40 H | 41 | 80 |

| Product | Bound Styrene (%) | Viscosity (ML 1+4 at 100°C) | Extender Oil |

|---|---|---|---|

| SBR 1500 | 23,5 | 52 | |

| SBR 1500 NF | 23,5 | 52 | |

| SBR 1502 G | 23,5 | 50 | |

| SBR 1502 | 23,5 | 52 | |

| SBR 1507 L | 23,5 | 30 | |

| SBR 1507 | 23,5 | 35 | |

| SBR 1712 | 23,5 | 49 | 37,5 - HI/AR |

| SBR 1712 G | 23,5 | 52 | 37,5 - HI/AR |

| SBR 1721 | 40 | 54 | 37,5 - HI/AR |

| SBR 1723 | 23,5 | 49 | 37,5 - TDAE |

| SBR 1739 | 40 | 54 | 37,5 - TDAE |

| SBR 1778 K | 23,5 | 46 | 37,5 - naphtenic |

| SBR 1745 T | 45 | 70 | 37,5 - TDAE |

| SBR 1783 | 23,5 | 49 | RAE – 37,5 |

| SBR 1789 | 40,0 | 54 | RAE – 37,5 |

| SBR 1793 | 23,5 | 49 | T-RAE—37,5 |

| Product | Bound Styrene (%) | Vinyl (%) | Viscosity (ML 1+4 at 100°C) | Extender Oil |

|---|---|---|---|---|

| SOL 5220 M | 26,5 | 26 | 54 | |

| SOL 5250 H | 20 | 55,5 | 74 | |

| SOL 5270 M | 21 | 63 | 50 | |

| SOL 5270 H | 21 | 63 | 65 | |

| SOL 5260 H | 28 | 55 | 75 | |

| SOL 5251 H | 21 | 55 | 77 | |

| SOL 5271 H | 21 | 63 | 67 | |

| SOL 1205 | 25 (20*1) | 10 | 50 | |

| SOL 6270 M | 25 | 63 | 47 | 37,5 - TDAE |

| SOL 6270 SL | 25 | 63 | 47 | 37,5 - TDAE |

| SOL C6270 L | 25 | 63 | 63 | 37,5 - TDAE |

| SOL 6360 SL | 34 | 48 | 47 | 37,5 - TDAE |

| SOL C6450 SL | 35,5 | 40 | 53 | 37,5 - TDAE |

| SOL 6440 H | 35,5 | 40 | 80 | 37,5 - TDAE |

| SOL 6361 H | 34 | 58 | 70*2 | 37,5 - TDAE |

| Product | CIS - 1,4 (%) | Viscosity (ML 1+4 at 100°C) |

|---|---|---|

| KBR 01 | Min. 96 | 45,0 |

| KBR 01 L | Min. 95 | 30,0 |

| KBR 710 S | 34,5 | 50 |

| KBR 710 H | 34,5 | 67 |

| KBR 820*1 | 40 | - |

| NdBR 40 | Min. 97 | 43 |

| NdBR 60 | Min. 97 | 63 |

*Functionalized Li-BR

| Product | Total Styrene (%) | Viscosity (ML 1+4 at 100°C) |

|---|---|---|

| KHS 68 | 68 | 61 |

| Product | Structure | Styrene (%) | Viscosity in a toluene solution at 25 wt-% (cps) | Oil content (phr) | |

|---|---|---|---|---|---|

| KTR-101 | Linear | 31,5 | 4,500 | ||

| KTR-103 | Linear | 31,5 | 2,000 | ||

| KTR-104 | Linear | 32,0 | 900 | ||

| KTR-201 | Linear | 31,5 | 1,200 | ||

| KTR-301 | Radial | 41 | / | 33,3 | |

| KTR-303 | Radial | 54,5 | 28,6 | ||

| KTR-401 | Radial | 31 | 23,8 | ||

| KTR-401 H | Radial | 32,5 | 21,5 | ||

| KTR-602 | Linear | 40,5 | 600 |

| Product | Cristallization rate | Viscosity (ML 1+4 at 100°C) | Applications / properties |

|---|---|---|---|

| DENKA M-30 | Medium | 38 ± 4 | General purposes, compounds with low viscosity |

| DENKA M-40 (new M 42) | Medium | 48 ± 5 | General purposes |

| DENKA M-41 | Medium | 48 ± 5 | As M-40 but with less roll sticking and mold staining |

| DENKA M-70 | Medium | 70 ± 10 | General purposes |

| DENKA M-100 | Medium | 100 ± 10 | Industrial goods |

| DENKA M-120 | Medium | 120 ± 10 | Sheets, hoses… |

| DENKA M 130 H | Medium | 1510-2700 (c) | Industrial goods |

| DENKA S 40 V | Very slow | 48 ± 5 | Industrial goods with resistance to law temperatures |

| DENKA ES-40 | Very slow | 43 ± 4 | Calendered sheets, extruded goods |

| DENKA ES-70 | Very slow | 75 ± 5 | Similar to ES- 40, with high viscosity |

| DENKA EM-40 | Medium | 48 ± 5 | Extruded goods with precise shapes |

| DENKA MT-40 | Medium | 48 ± 5 | Calendered sheets, extruded goods |

| DENKA MT-100 | Medium | 95 ± 10 | Extruded |

| DENKA PS-40 A | Slow | 35 - 55 | Belts, sponges..improved storage stability and low temperature resistance |

| DENKA DCR-30 | Slow | 65 ± 7 | Industrial goods with low temperature resistance |

| DENKA DCR-40 | Slow | 40 - 55 | Belts , sponges and molded goods |

| DENKA DCR-42A | Medium | 40 - 55 | Cables |

| Product | Viscosity (ML 1+4 at 125°C) | ENB (wt-%) | Ethylene (wt-%) | Oil content (phr) | MWD | Product form |

|---|---|---|---|---|---|---|

| COPOLYMER | ||||||

| KEP 020 P | 14 | 71 | N | P | ||

| KEP 070 P | 42 | 70,5 | N | P | ||

| KEP 110 | 26 | 51,5 | B | B | ||

| KEP 0530 | 30*(1+4) 100°C | 50,0 | M | B | ||

| KEP 2060 | 65 | 54,0 | B | B | ||

| TERPOLYMER | ||||||

| Low unsaturation diene | ||||||

| KEP 430 H | 43 | 1,6 | 57 | N | B | |

| KEP 435 | 33 | 2,3 | 56,5 | N | B | |

| Medium unsaturation diene | ||||||

| KEP 1030 F | 89 | 4,5 | 61,5 | N | FB | |

| KEP 210 | 23 | 5,7 | 65 | VB | B | |

| KEP 240 | 42 | 4,5 | 57 | M | B | |

| KEP 270 | 71 | 4,5 | 57 | M | B | |

| KEP 281 F | 92 | 5,7 | 67 | B | FB | |

| KEP 282 F | 90* (1+8) 125°C | 5,7 | 73 | M | FB | |

| KEP 2320 | 25 | 4,7 | 57,5 | BM | B | |

| KEP 2371 | 115* (1+8) 125°C | 7,0 | 70 | B | B | |

| KEP 2380 | 82* (1+8) 125°C | 5,7 | 55,5 | BM | SFB | |

| KEP 510 | 23 | 5,7 | 71 | VB | B | |

| KEP 570 F | 59 | 4,5 | 70 | N | FB | |

| KEP 570 P | 53 | 4,5 | 70 | N | P | |

| KEP 5770 | 73 | 5,0 | 74 | N | B | |

| KEP 6590 | 90(1+8) 125°C | 6,5 | 53 | N | B | |

| KEP 7141 | 27 | 4,5 | 51 | M | B | |

| High/ultra high unsaturation diene | ||||||

| KEP 330 | 28 | 7,9 | 56,5 | M | B | |

| KEP 350 | 56 | 8,0 | 57,0 | M | B | |

| KEP 370 F | 69 | 8,1 | 59,0 | M | FB | |

| KEP 650 | 49 | 8,7 | 59,0 | M | B | |

| KEP 650 L | 41 | 8,7 | 59,0 | M | B | |

| KEP 2480 | 81* (1+8) 125°C | 8,9 | 57,5 | BM | SFB | |

| KEP 8512 | 120*(1+8) 125°C | 8,0 | 55,0 | B | B | |

| KEP 9590 | 95* (1+8) 125°C | 10,0 | 52,0 | N | SFB | |

| KEP 9570E | 70*(1+8) 125°C | 10,0 | 55,0 | 20 | BM | SFB |

| OLIOESTESO | ||||||

| KEP 901 N | 52 | 4,8* | 69,5* | 100 | N | B |

| KEP 902 N | 52 | 4,5* | 66,5* | 100 | N | B |

| KEP 960 N | 56 | 5,7* | 70,0* | 50 | M | B; FB |

| KEP 980 N | 64 | 4,5* | 70,0* | 75 | N | B |

| KEP 4640 E | 56 | 4,5* | 64,0* | 75 | N | B |

MWD: N= NARROW, B=BROAD, VB=VERY BROAD

PRODUCT FORM: P=PELLET, F= FRIABLE BALE, B=DENSE BALE, SFB=SEMI FRIABLE BALE

Functional fillers

| Product | BET (m2/g) | Appearance/packaging |

|---|---|---|

| EBROSIL PD/GR | 185 | Powder / Granules Bag, big bag, bulk |

| EBROSIL H155AT | 155 | Microspheres |

| EBROSIL S-125 PD/GR | 125 | Powder / Granules Bag, big bag, bulk |

| EBROSIL SA 60 | 60 | Powder / Granules Bag, big bag, bulk |

MISTRON© Talc Series - a functional mineral for rubber

MISTRON© Talc Series products are functional minerals, not simple fillers.

MISTRON© VAPOR products provide the rubber formulator with flexibility to balance the benefits of improved processability with higher product performance. MISTRON© VAPOR products occupy a unique position in the rubber industry and have been used succesfully for more than 50 years.

MISTRON© VAPOR Talc Series - improve your mechanical properties!

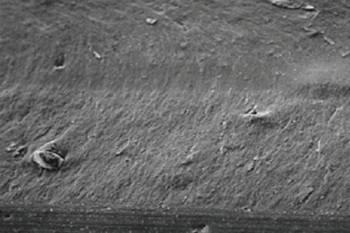

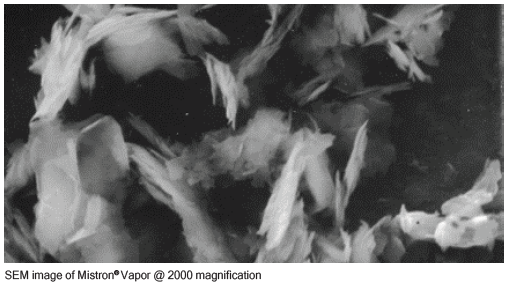

MISTRON© VAPOR is an ultra-fine, micro-lamellar, highly pure, hydreated magnesium silicate specifically developed for the rubber industry. Its platy morphology, organophilic nature, high aspect ratio and surface area result in superior reinforcement and rheology plus permeability resistance for thermoset rubbers.

MISTRON© VAPOR is an extremly soft mineral with a Mohs hardness of one. This property reduces wear on processing equipment compared with other minerals. MISTRON© VAPOR has less than 0.2% absorbed water, which eliminates pre-drying and allows it to be used in liquid-medium cure systems without encountering porosity problems. MISTRON© VAPOR is an electrical insulator and chemically resistant mineral eliminating electrochemical degradation in window seals and hoses plus providing solutions in wire and cable.

MISTRON© VAPOR functions as ...

... Processing Aid providing ...

- Reduced Mixing Times

- Lower Compound Viscosities

- Reduced Heat Generation

- Superior Compound Flow

- Improved Extrusion Rate and Quality

- Better Dispersion of Reinforcing Fillers

- Reduced Elasticity / Nerve

- Higher Green Strength

.. Reinforcement improving ...

- Tensile Properties

- Tear Properties

- Fatigue Performance

- Flaw Resistance

- Improved Thermal Performance

- Superior Weathering

... Improvement for wire and cable

- Chemical and Electrochemical Resistance

- Electrical Insulating Properties

MISTRON© HYPERPLATE™ Speciality talc

New Innovative MISTRON© HYPERPLATE™ ULTRA for Superior Barrier Performance

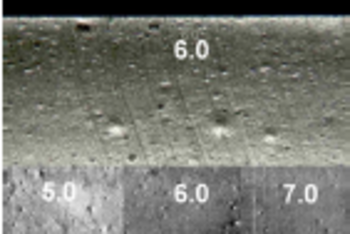

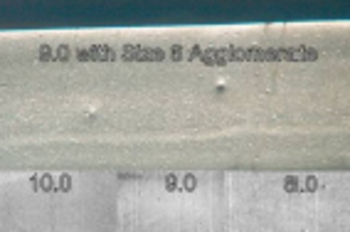

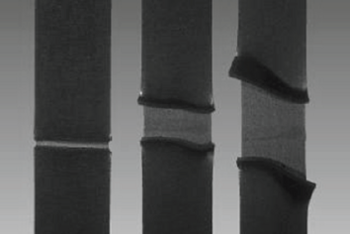

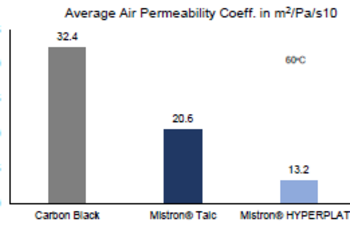

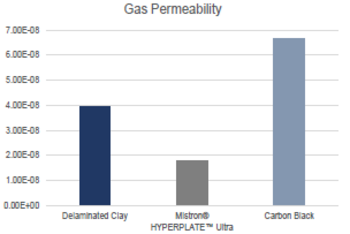

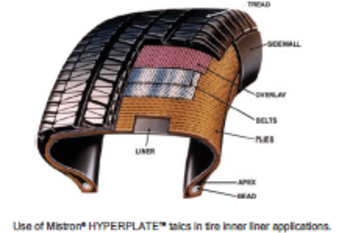

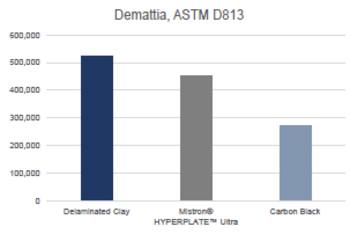

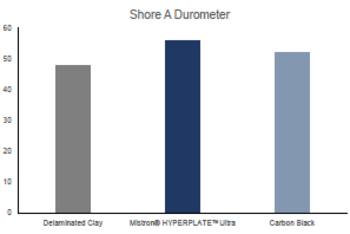

MAGRIS TALC has recently developed a higher aspect ratio HYPERPLATE™ talc for superior barrier performance. In extensive studies multiple talc grades has been tested and MISTRON© HYPERPLATE™ ULTRA was found to be the best performer in Gas Permeability (ASTM D1434) and DeMattia Flex Crack (ASTM D813) against the most commonly used Carbon Black Control and Clay. MISTRON© HYPERPLATE™ ULTRA's gas permeability is 3 times lowerand also sustained about twice the amount of DeMattia Flex Cycles when compared to the Carbon Black Control.

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| SILVERLINE© 002 | Natural white powder, bags | Dusting, relase agent talc | Excellent partioning low cost agents | 8,4 | 55 | 75 |

| VERTAL© 92 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 17,5 | 45 | Y72 |

| VERTAL© 97 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (powder) | Natural white powder, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (compacted) | White powder compacted, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR RE | Natural white powder, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness | 2,2 | 31 | 80 |

| MISTRON© VAPOR ULTRA | Natural white powder very fine, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness. Improve extrudate surface quality, enhanced elongation at break | 2 | 12 | 88 |

| MISTRON© CB* | Surface treated powder, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2,2 | 31 | 86 |

| MISTRON© CB6* | Surface treated and finer and densified, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2 | 25 | 88 |

| MISTRON© HYPERPLATETM | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,2 | 8 | 80 |

| MISTRON© HYPERPLATETM ULTRA | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,5 | 10 | 83 |

| MISTROFOAM©* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, foamed polymer products | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2,2 | 31 | 82 |

| MISTRON© ZSC* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance, higher dielectrical stregths, properties in wire and cable | 2 | 25 | 87 |

| MISTRON© TZ2* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2 | 25 | 87 |

| MISTROPHOBE* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, reaktive chemistry with any unsaturated cure system, that enhances hydrophobicity, wet electrical performance and mechanical properties | 2 | 25 | 88 |

* = surface treated

UPM BioMotion™ are wood-based renewable functional fillers from UPM Biochemicals for innovative and sustainable solutions in the chemical industry.

Given the urgent need to reduce CO2 emissions from rubber products, they offer a sustainable alternative to replace the two dominant fossil-based fillers in rubber products - carbon black and precipitated silica.

The Portfolio is based on biochemicals produced from certified sustainable and regional hardwood and sawmill waste in a biorefinery in Leuna.

The UPM BioMotion™ products can make a significant contribution to improving the sustainability of end-use applications in the rubber industry, in particular through weight reduction and significantly lower CO2 emissions. The functional fillers are mainly used in elastomers, which are used in various applications including the automotive industry, floor coverings and shoe soles.

The production process is patent-protected and unique worldwide.

In addition to the improved carbon footprint, UPM BioMotion™ products also have greater purity. Furthermore, they enable a weight saving of up to 25 percent in rubber applications compared to fillers based on fossil raw materials. For the automotive industry in particular, weight savings mean higher mileage, lower costs and an additional reduction in CO2 emissions.

Only recently, the European Rubber Journal ranked these products number four in the top 10 projects for new, sustainable elastomers. Furthermore, UPM Biochemicals' investment in the biorefinery in Leuna has made it to the finalists in the competition for the German Corporate Sustainability Award 2022 and has been shortlisted for Chemical Week's Sustainability Awards.

Based on its specific surface area ranging from 10 m²/g – 40 m²/g, they fall into the category of semi-reinforcing functional fillers. Due to the polar nature of its surface, RFFs show a strong interaction and reinforcement in polar rubbers, like NBR, AEM, ACM, and FKM. In non-polar rubbers, like EPDM, SBR, or NR, typically lower levels of reinforcement are achieved in direct comparison to traditional functional fillers with similar specific surface areas

Currently, there are three grades to offer with a different specific surface area between 10m2/g and 40m2/g. There is ongoing development to expand the product range shortly

They are available in pellet (granulate) format. They should be stored in a clean, dry space away from exposure to high temperatures, open flames. Pelletized Grades are much easier to handle due to significantly better flow and conveying properties. They would be commercially available in big bags (2m3) and low melting PE bags (EVA) ranging from 5kg to 20kg.

| UPM BioMotionTM | X10 | X20 | X30 |

|---|---|---|---|

| STSA Surface Area [m2/g] | 11 | 23 | 40 |

| pH | 6 - 10 | 6 - 10 | 6 - 10 |

| Sulfur Content [%[ | < 0.2 | < 0.2 | < 0.2 |

| Benzo[a]pyrene [ppm] | < 0.1 | < 0.1 | < 0.1 |

| Each of 22 FDA PAHs [ppm] | < 1 | < 1 | < 1 |

| Loss on Drying [%] | < 3 | < 3 | < 3 |

Carbon blacks

| Characteristic | ASTM Test Method | N-115 | N-121 | N-134 | N-220 | N-234 | N-326 | N-330 | N-339 | N-347 | N-375 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 113 | 131 | 127 | 114 | 125 | 72 | 102 | 120 | 124 | 114 |

| Iodine no. (mg/g) | D 1510 | 160 | 121 | 142 | 121 | 120 | 82 | 82 | 90 | 90 | 90 |

| Ash (% max.) | D 1506 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 500 | 250 | 250 | 250 | 200 | 350 | 200 | 500 | 200 | 250 |

| Nitrogen surface area (m2/g) | D 6556 | 137 | 122 | 143 | 119 | 119 | 78 | 82 | 90 | 85 | 93 |

| Appearance | - | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets |

| Characteristic | ASTM Test method | N-539 | N-550 | N-650 | N-660 | N-772 |

|---|---|---|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 111 | 121 | 122 | 90 | 65 |

| Iodine no. (mg/g) | D 1510 | 43 | 43 | 36 | 36 | 30 |

| Ash (% max.) | D 1506 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 100 | 200 | 250 | 250 | 500 |

| Nitrogen surface area (m2/g) | D 6556 | 38 | 40 | 36 | 35 | 32 |

| Appearance | - | Black pellets | Black pellets | Black pellets | Black pellets | Black pellets |

| Characteristic | ASTM Test method | N-550 LG | N-650 LG |

|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 121 | 122 |

| Iodine no. (mg/g) | D 1510 | 43 | 36 |

| Ash (% max.) | D 1506 | 0,5 | 0,5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 20 | 20 |

| Nitrogen surface area (m2/g) | D 6556 | 40 | 36 |

| Appearance | - | Black pellets | Black pellets |

| Characteristic | ASTM Test method | MT N-990 | MT N-991 |

|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 40 | 40 |

| Iodine no. (mg/g) | D 1510 | 8 | 8 |

| pH value | D 1512 | 9 | 9 |

| Ash (% max.) | D 1506 | 0,1 | 0,1 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 27 | 34 |

| Bulk density (kg/m3) | D 1513 | 500 | 360 |

| Appearance | - | Grey-black pellets | Grey-black pellets |

| Characteristic | ASTM Test Method | LB/P | LB/S |

|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 40 | 40 |

| Iodine no. (mg/g) | D 1510 | 8 | 8 |

| pH value | D 1512 | 9 | 9 |

| Ash (% max.) | D 1506 | 0,1 | 0,1 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 27 | 34 |

| Bulk density (kg/m3) | D 1513 | 500 | 360 |

| Appearance | - | Black pellets | Black pellets |

Rubber-Metal Bonding Agents

| PARLOCK | |

|---|---|

| PARLOCK PC 6012 | Universal rubber-to-metal adhesive. Parlock PC 6012 can be optionally applied with Parlock PM05 primer. Parlock PC 6012 bonds different rubber compounds and elastomers (NR, IR, SBR, BR, NBR and IIR) and some plastics. The combination of Parlock PC 6012 with Parlock PM05 primer offers excellent adhesion values. |

| PARLOCK PC 6016 | Universal rubber-to-metal adhesive. Parlock PC 6016 can be optionally applied with Parlock PM05 primer. Parlock PC 6016 bonds different rubber compounds and elastomers (NR, IR, CR, SBR, BR, NBR, IIR, EPDM, ECO and CSM) and some plastics. The combination of Parlock PC 6016 with Parlock PM05 primer offers excellent adhesion values and is especially suitable for soft NR and NBR in TM- and IM- procedures. |

| PARLOCK PM 05 | Used with Parlock adhesive to bond a wide variety of vulcanized and unvulcanized rubber compounds to metal and other rigid substrates. |

Learn more about the LUVOMAXX® Business of Lehmann&Voss&Co.: www.lehvoss.de/en/Rubber

Your personal contact